- 2U Chassis

- 3U Chassis

- 4U Chassis

- NAS / DAS

- Desktop

- OEM / ODM

Testing & Compliance Safety, EMI/ESD, Environmental

|

Our Testing Options »We recommended at minimum testing any system for FCC compliance. FCC part 15 covers basic EMI and EMC testing and is required for resale within the United States. If you plan on selling to markets outside the US we highly recommend first testing for CE for three reasons. First is that it is mandatory for resale in the EU. Secondly because CE has testing standards that exceed the metrics of the FCC test, any system that passes CE will be FCC approved. Third, testing for CE includes basic system safety testing. The benefit of this route is that with CE safety you can submit your test results and receive UL or MET listing. Additional certifications we can assist in attaining include:

|

|---|---|

Electromagnetic Compatibility (EMC) »EMC consists of unintentional or intentional electromagnetic noise that your product generates and sends out into space. Because this noise has the potential to jam other equipment or transmitters that use specific frequencies we are required to limit the amount of noise that products are allowed to send out into space.

| |

Immunity (EMI) »Immunity can be thought of as your systems ability to reject noise coming in from an outside source. Testing for immunity is designed to show that your product can be powered around other unprotected systems or equipment and still operate as intended. EMI testing includes the following conditions and more:

|

IP (Ingress Protection) Testing »Protection from water, dust, ice, chemical or splash intrusionIngress Protection (IP) tests are typically performed on enclosures to determine the level of protection needed from water, dust, ice, chemical or splash intrusion. Sliger works closely with our environmental stress testing lab partners to perform Ingress Protection testing that satisfies the following categories:

|

|

|---|

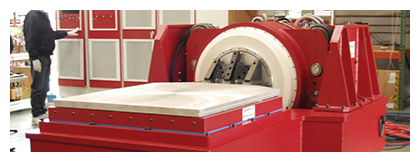

Vibration & Shock Testing »Low and High Displacement, Free-fall Shock and VibrationFrom deployment environment vibration such as trains and helicopters, to shock and drop during shipping, our simulated environment testing ensures your packages arrive operational and work reliably in any environment. We are familiar with the wide body of vibration and shock specifications across many industries.

|

|

|---|

Thermal & MTBF Testing »Establish your systems temperature tolerance and component lifecycleBy exposing the product to high and low levels of controlled temperature, humidity and pressure; we can establish (before production) under what conditions your product may experience performance issues. Additionally, thermal testing can establish estimates of the MTBF (Mean Time Between Failure) of the product, and all components within the product. All of this can be established when actual lifespan has yet to be determined under normal use.

|

|

|---|

|

Optional Testing »Customized testing for your project specific needsWe understand the need for a wide variety of environmental product testing. Our laboratory partners are equipped with a full range of fixed and dynamic test capabilities to meet the most demanding industry test standards.

|

|---|---|

Contact one our project engineers at 1 (775) 356-5595 or engineering@sliger.com for any questions or quotes! |

|